It all starts with unpasturised cow’s milk,

coming from local farms with well-defined, strictly regulated production processes, and from cows only milked twice a day with free access to an automatic milking system.

Raw milk

The raw milk must be produced in the geographical area set in the Product Specifications. It is partially skimmed by natural surface skimming.

Copper Cauldrons

1.000 litres of this partially skimmed milk is then placed inside traditional bell-shaped copper cooking cauldrons (or vats, Each cauldron produces two wheels of cheese, called “twin wheels”.

Whey

Then the whey produced the day before is added. Full of lactic acid bacteria, whey is the perfect way to trigger the transformation of milk into cheese.

Heat

Once the whey has been added, the milk is brought to a temperature of 31-33°C(88-91° F)

Rennet

Once the whey has been added, the milk is brought to a temperature of 31-33°C (88-91° F) and the calf rennet is added.

Breaking of the curd

The curd is then broken with a giant whisk (spino) into pieces which are as small as grains of rice

Heating

The broken curd is then heated to a maximum temperature of 56° C (136° F). Once this temperature is reached, the cooking is completed, and the curd granules begin to settle at the bottom of the copper cauldron.

Resting

The curd granules are left to rest in the copper cauldron, immersed in the whey, for a maximum of 70 minutes from the end of the heating phase, so that they aggregate, to form a compact mass.

Lifting

Using a sort of a wooden shovel (pala) and a linen cloth (schiavino), the curd mass is raised from the bottom of the cauldron and cut into two equal parts, in order to create two twin wheels.

Extraction

Each of the two wheels are removed from the copper cauldron, wrapped in linen cloths and placed on a shelf – the “spersola”.

First molding

Each wheel is placed into a special mould, the fascera, made of suitable plastic material. A heavy object of the same material is then placed on top of the cheese to place pressure.

Marks of origin

After about 12 hours, a piece of plastic (fascera) engraved with the Marks of Origins is inserted.

Casein Plate

Then a casein plate, with a specific ID code is placed on the top face of the wheel, this is crucial when identifying the traceability of each wheel.

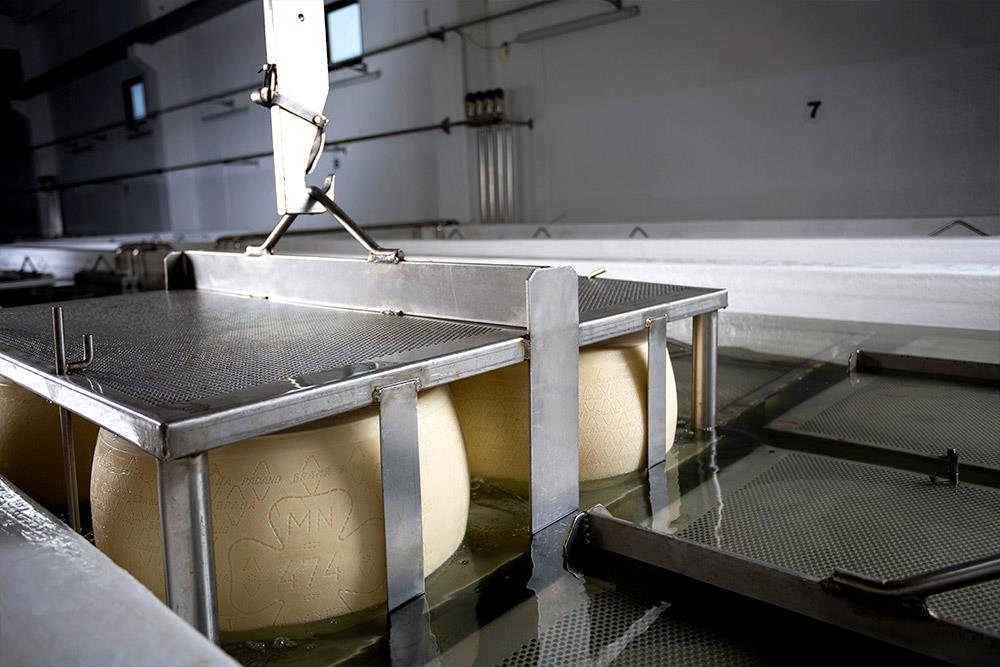

Salting

Two days later, the process of salting (salatura) starts: the cheese wheels are soaked in brine, a solution of water and salt. This step can take from 12 to 25 days, depending on the saline solution and the size of the wheel.

Drying

Once the salting is finished, the wheels are taken into a “hot room” (camera calda) where they will dry for a few hours.

Ageing

Finally, the cheese wheels will be taken to a specific maturing warehouse, where they will be left to age for a minimum of 9 months.