Ageing and controls

After 9 months of ageing, control process begins.

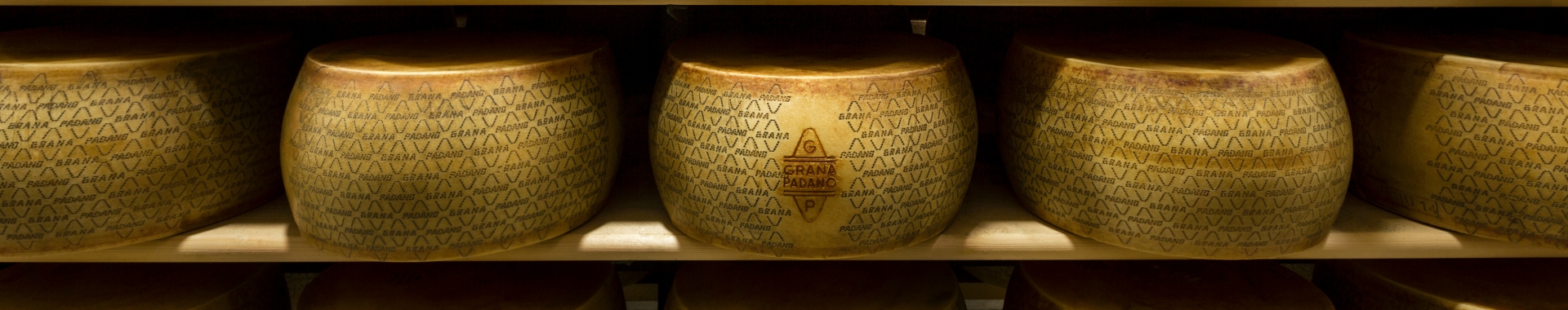

Maturing Warehouses

The maturing warehouses are insulated and designed with equipment that regulate the temperature, the moisture level and the required aeration.

Time

In total, the ageing can last from a minimum of nine months to more than 20 months. During this period, the cheese will undergo various important physical-chemical changes. Through these changes it will develop its unique taste.

The care

The wheels are looked after, cleaned and turned over about every 15 days. This work is now done by using special automatic turning and brushing machines.

Controls

After 9 months of ageing, technicians will test each wheel with a special small steel hammer.

Small hammer

This process requires great expertise and experience, giving the technicians the opportunity to spot any defects that may have been caused by abnormal fermentation.

Needle

They might also use a special needle: this procedure is implemented to check the scent and flavour of the cheese without damaging the wheel.

Probe

To be absolutely certain the cheese is of the highest quality, a small instrument (which doesn’t damage the wheel) will be used to extract a small sample, 1cm in diameter and 7-8 cm long to be exact. This will be tested to check the fragrance, colour and texture of the paste.

Fire-branded marking

If the wheel meets the requirements according to the Product Specifications, it will receive the fire-branded mark which certifies the quality of the cheese and its official “Grana Padano PDO” status.

Screening

The wheels that do not meet the Product Specifications requirements will be “etched”: the diamond shaped “Grana” and “Padano” lozenges will be covered with “X” marks.

Our gallery